Cellular confinement systems (CCS)—also known as geocells—are widely used in construction for erosion control, soil stabilization on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth retention.[1] Typical cellular confinement systems are geosynthetics made with ultrasonically welded high-density polyethylene(HDPE) strips or novel polymeric alloy (NPA)—and expanded on-site to form a honeycomb-like structure—and filled with sand, soil,rock, gravel or concrete.

The strength and stiffness of pavement layers determines the performance of highway pavements while aggregate use impacts the cost of duration of installation; therefore alternatives are needed to improve pavement quality using new materials with less aggregate usage (Rajagopal et al 2012).[19] Geocells are recognized as a suitable geosynthetic reinforcement of granular soils to support static and moving wheel loads on roadways, railways and similar applications. But stiffness of the geocells was identified as a key influencing factor for geocell reinforcement, and hence the rigidity of the entire pavement structure.

Utilizing recent advances in polymer and nano technology, extensive R&D was carried out to improve geocell wall stiffness, thermal and elastic properties and long term creep resistance by PRS-Med. The result was a cellular confinement system (PRS-Neoweb) manufactured from Neoloy, a novel polymeric alloy (NPA). NPA is a composite alloy of polyamide nano-fibers dispersed in a polyethylene matrix. It provides ductility similar to HDPE with elastic behavior similar to engineering thermoplastics, to create a stiffer CCS more suitable for heavy duty applications, such as base reinforcement of highways, railways, container yards, etc. that are subject to long-term heavy static and dynamic loading.

Laboratory plate loading tests, full-scale moving wheel tests, and field demonstrations showed that the performance of geocell-reinforced bases depends on the elastic modulus of the geocell. Geocells with a higher elastic modulus had a higher bearing capacity and stiffness of the reinforced base. NPA Geocells showed higher results in ultimate bearing capacity, stiffness, and reinforcement relative to geocells made from HDPE (Pokharel, et al, 2009).[21] NPA geocells showed better creep resistance and better retention of stiffness and creep resistance particularly at elevated temperatures, verified by plate load testing, numerical modeling and full scale trafficking tests (Han, et al. 2011)[](Pokharel, et al 2011).

Application vs. long-term performance

CCS have been successfully installed in thousands of projects worldwide. However, it is incumbent to differentiate between low load applications, such as slope and channel applications, and new heavy-duty applications, such as in the base layer of asphalt pavement structures of heavily trafficked motorways and highways. While all polymeric materials used in CCS creep over time and under loading, the question is; what is the rate of degradation, under which conditions, how will this impact performance, and when will it fail?

The lifespan of CCS in slope protection applications, for example, is less critical as vegetative growth and root interlock stabilize the soil. This in effect compensates for any long-term loss of confinement in the CCS. Similarly, load support applications for low volume roads that are not subject to heavy loading usually have a short design life; therefore minor loss of performance is tolerable. However, in critical applications such as reinforcement of the structural layer of asphalt highway pavements, long-term dimensional stability is critical. The required design life for such roads under heavy traffic loads is typically 20–25 years, requiring verifiable long-term durability.

Development of standards for testing CCS

The few standards for CCS were developed more than 40 years ago and have changed little since. Some of the current standards evolved from 2D planar geosynthetics, and as such, do not reflect the composite behavior of 3D geometry of CCS, nor do they test long-term parameters such as: dynamic loading, permanent plastic deformation, effect of temperatures, environmental durability, etc.

On the other hand ISO/ASTM procedures have been developed for testing polymers in the space and automobile industries, as well as for other geosynthetic products. These new standards for CCS were proposed and under discussion by leading experts in geosynthetics in ASTM technical committee D-35. The stated goal is to set new industry standards that more accurately reflect 3D cellular confinement system geometry and material performance in the field rather than lab tests of individual strips and virgin materials that are typically used today.

Applications

Roadway load support

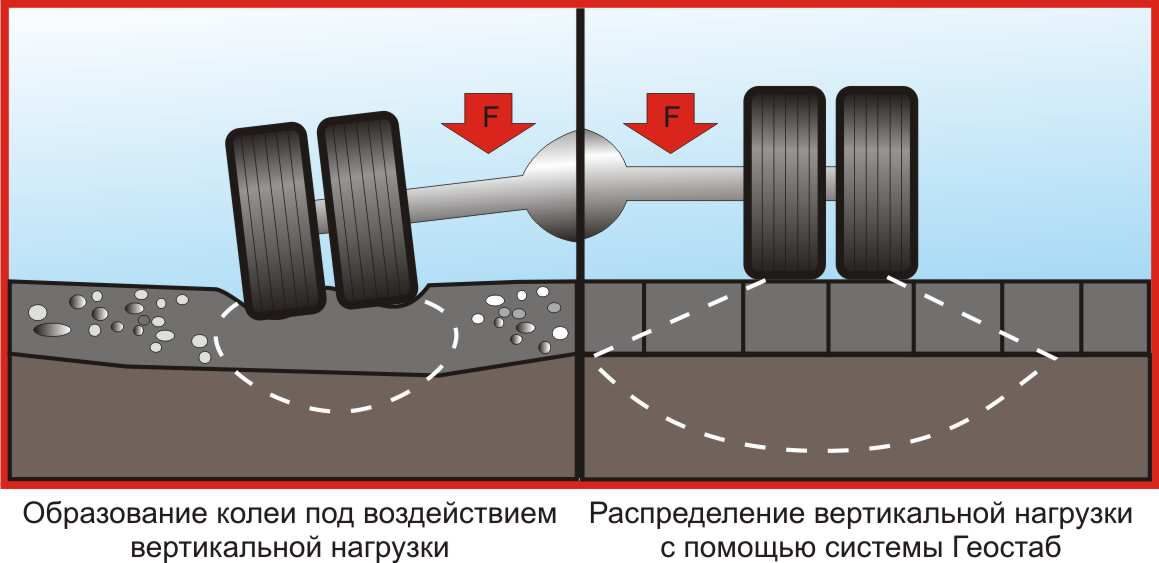

Cellular Confinement Systems (CCS) have been used to improve the performance of both paved and unpaved roads by reinforcing the soil in the subgrade-base interface or within the base course. The effective load distribution of CCS creates a strong, stiff cellular mattress. This 3D mattress reduces vertical differential settlement into soft subgrades, improves shear strength, and enhances load-bearing capacity, while reducing the amount of aggregate material required to extend the service life of roads. As a composite system, cellular confinement strengthens the aggregate infill, thereby simultaneously enabling the use of poorly graded inferior material (e.g. local native soils, quarry waste or recycled materials) for infill as well as reducing the structural support layer thickness. Typical load support applications include reinforcement of base and subbase layers in flexible pavements, including: asphalt pavements; unpaved access, service and haul roads; military roads, railway substructure and ballast confinement; working platforms in intermodal ports; airport runways and aprons, permeable pavements; pipeline road support; green parking facilities and emergency access areas.

Steep soil slope and channel protection

The three-dimensional lateral confinement of CCS along with anchoring techniques ensures the long-term stability of slopes using vegetated topsoil, aggregate or concrete surfacing (if exposed to severe mechanical and hydraulic pressures). The enhanced drainage, frictional forces and cell-soil-plant interaction of CCS prevents downslope movement and limits the impact of raindrops, channeling and hydraulic shear stresses. The perforations in the 3D cells allow the passage of water, nutrients and soil organisms. This encourages plant growth and root interlock, which further stabilizes the slope and soil mass, and facilitates landscape rehabilitation. Typical applications include: construction cut and fill slopes and stabilization; road and rail embankments; pipeline stabilization and storage facility berms; quarry and mine site restoration; channel and coastline structures. They can be built as an underlying mass or as a facing.

Earth retention

CCS provide steep vertical mechanically stabilized earth structures (either gravity or reinforced walls) for steep faces, walls and irregular topography. Construction of CCS earth retention is simiplified as each layer is structurally sound thereby providing access for equipment and workers, while eliminating the need for concrete formwork and curing. Local soil can be used for infill when suitable and granular, while the outer faces enable a green or tan fascia of the horizontal terraces/rows utilizing topsoil. Walls also can be used for lining channels and in cases of high flow, it is required that the outer cells contain concrete or cementious slurry infill. CCS have been used to reinforce soft or uneven soil foundations for large area footings, for retaining wall strip footings, for load sharing of covers over pipelines and other geotechnical applications.

Reservoirs and landfills

CCS provides membrane liner protection, while creating stable soil, berms and slopes, for non-slip protection and durable impoundment of liquids and waste. Infill treatment depends on the contained materials: concrete for ponds and reservoirs; gravel for landfill drainage and leachates, vegetated infill for landscape rehabilitation. Concrete work is efficient and controlled as CCS functions as ready-made forms; CCS with concrete forms a flexible slab that accommodates minor subgrade movement and prevents cracking. In medium and low flow-velocities, CCS with geomembranes and gravel cover can be used to create impermeable channels, thereby eliminating the need for concrete.

Sustainable construction

CCS is a green solution that makes civil infrastructure projects more sustainable. In load support applications, by reducing the amount and type of infill needed to reinforce soil, the usage of haul and earthmoving equipment is reduced. This in turn decreases fuel use, pollution and the carbon footprint, and at the same time minimizes on-site disruption from dust, erosion and runoff. When used for slope applications, perforated CCS provides excellent soil protection, water drainage and growth stratum for plants. The long-term design life of advanced CCS technology means that maintenance and the associated environmental costs are significantly reduced, as are long-term economic costs.